Understanding MEP

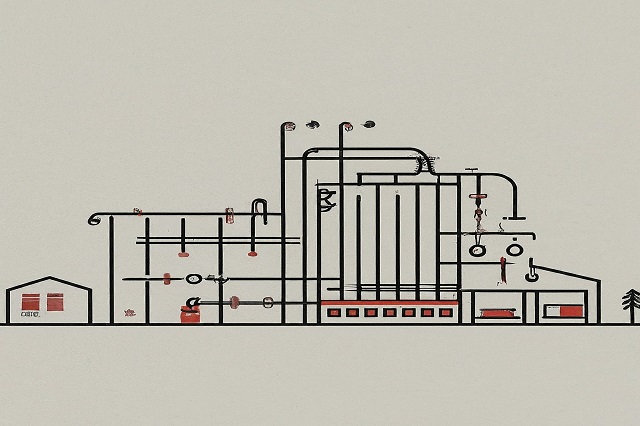

MEP, or Mechanical, Electrical, and Plumbing, systems are the lifeblood of any industrial facility. These interconnected networks ensure the safe, efficient, and sustainable operation of the facility. From providing essential utilities to supporting complex manufacturing processes, MEP systems play a critical role in achieving optimal productivity.

Key Components of MEP Systems

-

Mechanical Systems:

- HVAC (Heating, Ventilation, and Air Conditioning): Regulates temperature, humidity, and air quality for both human comfort and process requirements.

- Piping Systems: Transports water, steam, compressed air, and other fluids for various industrial processes.

- Fire Protection Systems: Includes sprinklers, fire alarms, and smoke detection systems to safeguard the facility and its occupants.

-

Electrical Systems:

- Power Distribution: Delivers electricity to various equipment and machinery throughout the facility.

- Lighting Systems: Provides adequate illumination for work areas, safety, and security.

- Control Systems: Manages and automates the operation of various equipment and processes.

-

Plumbing Systems:

- Water Supply: Provides potable water for drinking, sanitation, and industrial processes.

- Wastewater Disposal: Collects and treats wastewater before discharging it into the sewer system or other approved outlets.

The Importance of MEP in Industrial Facilities

- Safety: MEP systems ensure a safe working environment by providing adequate ventilation, fire protection, and electrical safety measures.

- Efficiency: Well-designed and maintained MEP systems can optimize energy consumption and reduce operational costs.

- Productivity: Reliable and efficient MEP systems support uninterrupted production processes and minimize downtime.

- Compliance: MEP systems must comply with relevant building codes, safety standards, and environmental regulations.

Challenges and Trends in MEP

- Energy Efficiency: The increasing focus on sustainability has led to a demand for more energy-efficient MEP systems.

- Automation and IoT: The integration of automation and Internet of Things (IoT) technologies is transforming MEP systems, enabling remote monitoring, predictive maintenance, and enhanced control.

- Complexity: Industrial facilities often have complex and specialized MEP requirements, necessitating careful planning and coordination.

The Role of Electromechanical Companies and Contractors

Electromechanical companies and electromechanical contractors specialize in designing, installing, and maintaining MEP systems. They offer a wide range of services, including:

- MEP design and engineering

- MEP installation

- MEP maintenance and repair

- Energy efficiency upgrades

- Automation and control systems

By partnering with reputable MEP contracting companies, industrial facilities can ensure that their MEP systems are designed, installed, and maintained to the highest standards, maximizing efficiency, safety, and productivity.

Conclusion

MEP systems are essential for the successful operation of industrial facilities. By understanding the components, importance, and challenges associated with MEP, facility managers can ensure that their facilities are equipped with reliable and efficient infrastructure to support their specific needs.

Would you like to know more about a specific aspect of MEP systems or discuss a particular industrial application?

Contact Midas Electromechanical Contracting for all your MEP needs in the below link